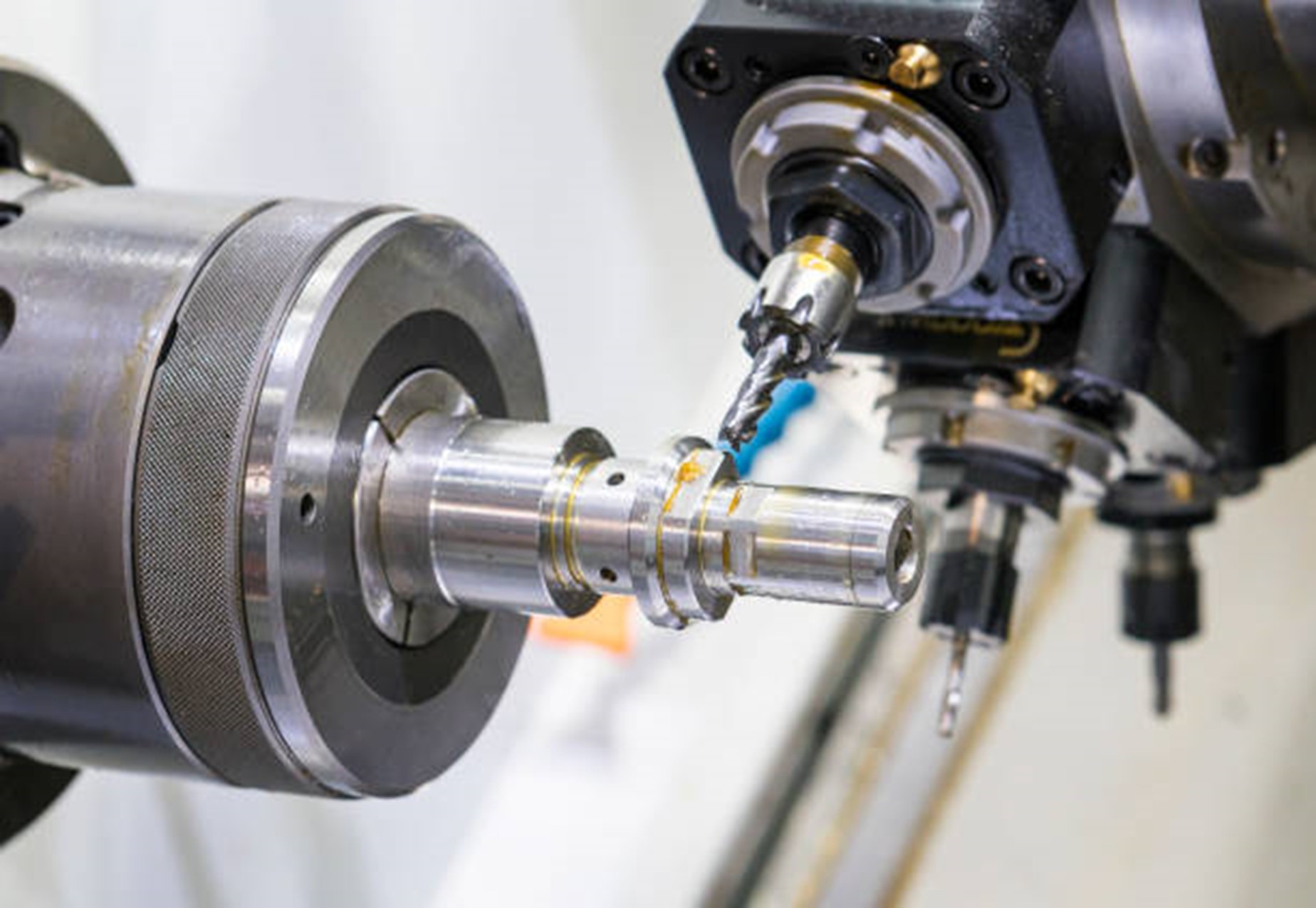

In the realm of manufacturing, the pursuit of cost-effectiveness is an ever-present challenge. It’s the delicate balance of achieving efficiency without compromising quality—a balance that can significantly impact a company’s bottom line. In this exploration, we delve into the world of cost-effective manufacturing, with CNC Turning as our guiding star, to uncover the secrets of efficient production while maintaining the highest standards of excellence.

The Nexus of Cost and Efficiency

Cost-effectiveness and efficiency share an inseparable bond in the world of manufacturing. The ability to produce quality components and products efficiently is a linchpin of success. It’s a dance where every move matters, and the partner that can lead this dance with finesse often takes center stage. CNC Turning is one such partner, adept at harmonizing cost and efficiency.

Advantages of CNC Turning in Cost-Effective Manufacturing

The advantages CNC Turning offers in cost-effective manufacturing are akin to a well-tuned orchestra playing in unison. First and foremost, precision is its virtuoso performance. Every cut, every rotation, and every detail is executed with impeccable accuracy, minimizing material waste and reducing rework costs.

Efficiency is another virtuoso in this orchestra. With the ability to produce components swiftly, it accelerates production timelines and reduces lead times. In the world of cost-effective manufacturing, time is money, and it is a valuable time-saving tool.

Minimizing Material Waste

CNC Turning’s contribution to cost-effective manufacturing starts with minimizing material waste. Precision machining ensures that each cut counts, leaving little room for error or excessive waste. In a world increasingly conscious of sustainability, this reduction in waste is not just economical but environmentally responsible.

Enhancing Operational Efficiency

Operational efficiency is the cornerstone of cost-effective manufacturing, and CNC Turning plays a pivotal role in enhancing it. Its ability to streamline production processes, from design to finished product, is a game-changer. Quick turnarounds are the name of the game, allowing businesses to stay competitive in today’s dynamic markets.

Customization and Adaptability

In a world where customization and adaptability are key differentiators, CNC Turning shines. It accommodates intricate and customized designs, ensuring that customer demands are met with precision and versatility. In the pursuit of cost-effectiveness, this adaptability offers a competitive edge.

Quality Assurance and Consistency

No discussion of cost-effective manufacturing is complete without highlighting the importance of quality assurance. CNC Turning, with its precision and consistency, contributes significantly to maintaining quality standards. It reduces the likelihood of costly rework and errors, ensuring that each component meets the highest quality benchmarks.

Conclusion

In the complex and demanding world of manufacturing, achieving cost-effectiveness is a quest that often defines success. CNC Turning, with its precision, efficiency, and versatility, emerges as a formidable ally in this journey. As you navigate the path of cost-effective manufacturing, consider the role that CNC Turning can play in orchestrating efficiency without compromising quality. It’s a conductor that ensures every note is played with precision and every movement is a step towards cost-effectiveness.