Introduction:

In the realm of temperature sensing technology, RTD sensors stand out for their accuracy, reliability, and versatility. Whether in industrial settings, scientific laboratories, or consumer electronics, RTD sensors play a crucial role in monitoring and controlling temperature with precision. However, with a plethora of providers in the market, choosing the right RTD sensor supplier can be daunting. In this comprehensive guide, we delve into the world of RTD sensors, their applications, and provide valuable insights to help you select the perfect provider for your needs.

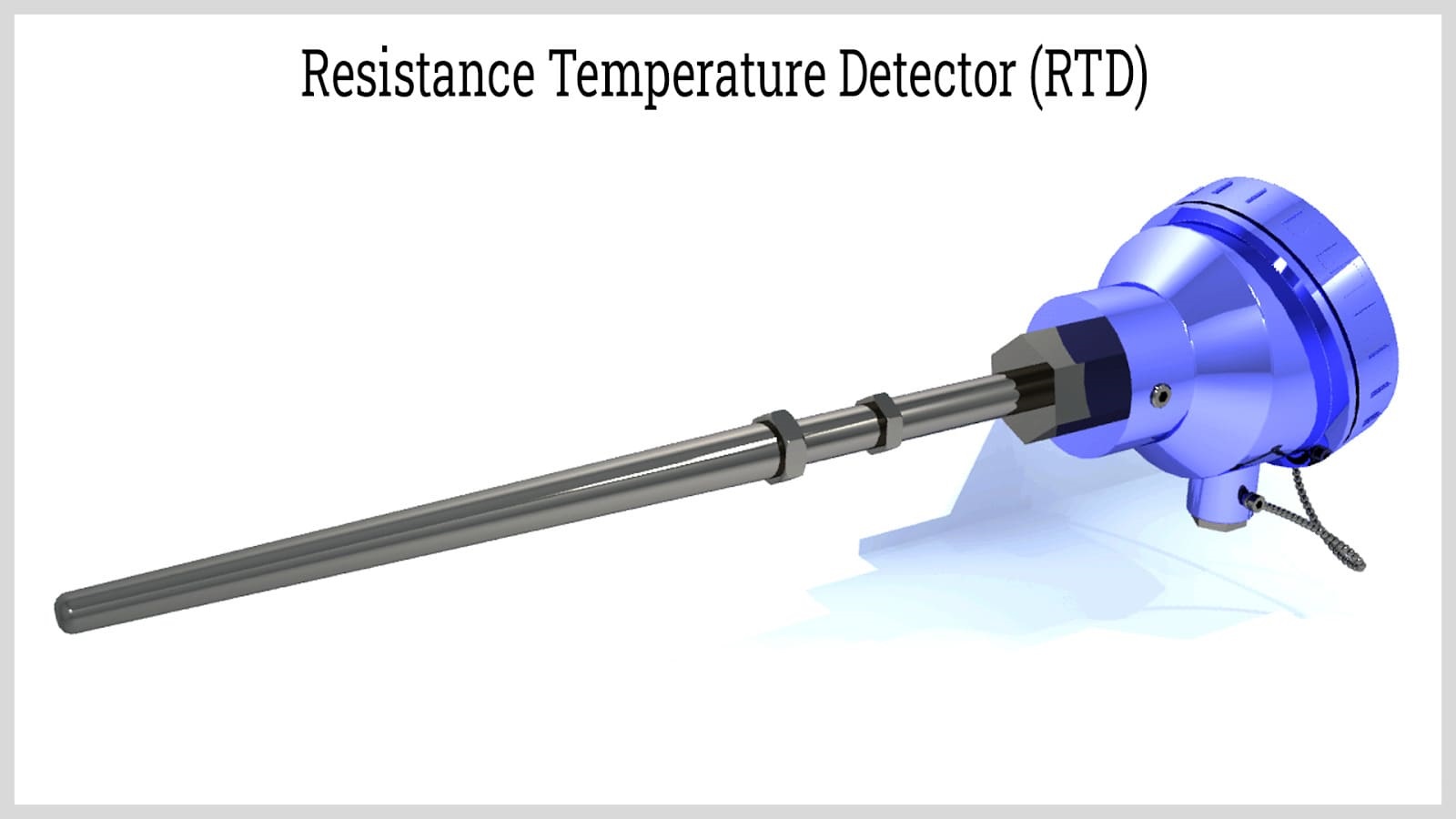

Understanding RTD Sensors:

Resistance Temperature Detectors (RTDs) are temperature sensors that rely on the principle of electrical resistance variation with temperature change. Typically made of pure metals like platinum, RTDs exhibit a predictable change in resistance in response to temperature fluctuations. This characteristic makes them highly accurate and stable across a wide temperature range.

RTDs operate based on the fundamental relationship between temperature and electrical resistance, as described by the Callendar-Van Dusen equation. This equation allows for precise calibration and accurate temperature measurement, making RTDs indispensable in industries where temperature control is critical.

Applications of RTD Sensors:

The versatility of RTD sensors enables their deployment across various industries and applications:

Industrial Processes:

RTD sensors are extensively used in industrial processes such as manufacturing, chemical processing, and HVAC systems for temperature monitoring and control. Their high accuracy and reliability ensure optimal process efficiency and product quality.

Aerospace and Automotive:

In aerospace and automotive applications, where extreme temperatures are common, RTD sensors provide vital temperature data for engine performance monitoring, cabin climate control, and thermal management systems.

Healthcare and Pharmaceuticals:

RTD sensors play a crucial role in healthcare equipment, pharmaceutical manufacturing, and research laboratories, ensuring precise temperature control for sensitive materials and processes.

Food and Beverage Industry:

In food processing and storage facilities, RTD sensors help maintain optimal temperatures to preserve food quality, prevent spoilage, and ensure regulatory compliance.

Environmental Monitoring:

RTD sensor is used in environmental monitoring systems to measure temperature variations in air, water, and soil, aiding in climate research, pollution control, and weather forecasting.

Choosing the Right RTD Sensor Provider:

Selecting the right RTD sensor provider is paramount to ensuring the reliability and performance of your temperature monitoring system. Here are some factors to consider when evaluating RTD sensor suppliers:

Quality and Reliability:

Look for providers known for manufacturing high-quality RTD sensors that adhere to industry standards and undergo rigorous testing procedures to ensure accuracy and reliability.

Customization Options:

Opt for a provider that offers customization options to tailor RTD sensors to your specific application requirements, including temperature range, probe length, and mounting configurations.

Calibration Services:

Choose a supplier that provides calibration services to certify the accuracy of RTD sensor and ensure compliance with regulatory standards.

Technical Support:

Assess the provider’s technical support capabilities, including expertise in RTD sensor technology, responsive customer service, and troubleshooting assistance.

Cost-Effectiveness:

While price is an important consideration. Prioritize value over cost alone by evaluating factors such as sensor quality, performance, and long-term reliability.

Reputation and Experience:

Select a reputable RTD sensor and Flange tubular heater provider with a proven track record of delivering quality products and satisfactory customer experiences. Research customer reviews, testimonials, and case studies to gauge the provider’s credibility and reliability.

Conclusion:

RTD sensor are indispensable tools for precise temperature measurement and control across various industries and applications. By understanding the principles of RTD sensor technology and considering key factors such as quality, customization options, calibration services, technical support, cost-effectiveness, and reputation. You can confidently choose the right provider to meet your temperature-sensing needs. Whether you’re optimizing industrial processes, monitoring environmental conditions, or ensuring product quality and safety. Partnering with a trusted RTD sensor provider is essential for achieving accurate and reliable temperature measurements.