In the ever-evolving realm of structural engineering, 3D rebar detailing has emerged as a game-changer, revolutionizing the way we approach construction projects. This blog post is your comprehensive guide to mastering the intricacies of 3D rebar detailing, exploring advanced techniques, benefits, and the future landscape of construction technology.

Understanding the Basics of 3D Rebar Detailing

Before delving into the intricacies, it’s crucial to establish a solid understanding of the fundamentals. 3D rebar detailing is a process that involves creating detailed three-dimensional models of reinforced concrete structures. Unlike traditional 2D detailing, 3D rebar detailing provides a more accurate and visual representation of the entire structure, allowing for better decision-making and collaboration among stakeholders.

One of the primary advantages of 3D rebar detailing lies in its ability to identify clashes and conflicts early in the design phase. This proactive approach significantly reduces the likelihood of errors during construction, saving both time and resources. By utilizing Building Information Modeling (BIM) technology, engineers can seamlessly integrate 3D rebar detailing into their workflow, fostering a more collaborative and efficient project environment.

Challenges and Future Trends

While the benefits of 3D rebar detailing are evident, challenges persist, including the initial learning curve associated with adopting new software and the need for skilled personnel. However, as the industry continues to embrace this technology, training programs and educational initiatives are emerging to bridge the skills gap.

Looking ahead, the future of 3D rebar detailing holds exciting possibilities. Machine learning and artificial intelligence are expected to further enhance the capabilities of BIM software, automating repetitive tasks and providing even more sophisticated analysis tools. The integration of augmented reality into the detailing process may also become a reality, allowing engineers to visualize and interact with the 3D model on the construction site.

Advanced Techniques in 3D Rebar Detailing

1. Parametric Modeling for Precision

Parametric modeling is a key technique that empowers engineers to create intelligent 3D models with dynamic properties. By defining parameters and relationships between elements, changes made to one part of the model automatically propagate throughout the entire structure. This not only enhances precision but also streamlines the modification process, ensuring that adjustments are seamlessly reflected in the entire project.

2. Clash Detection and Resolution

In the realm of 3D rebar detailing, clash detection is a crucial feature that identifies potential conflicts between different structural elements. Through advanced clash detection algorithms, engineers can pinpoint clashes early in the design phase, preventing costly errors during construction. The active resolution of clashes ensures that the final construction aligns with the intended design, enhancing structural integrity and safety.

Benefits of Implementing 3D Rebar Detailing

1. Enhanced Visualization and Communication

One of the standout advantages of 3D rebar detailing is its ability to provide a realistic visual representation of the project. This not only aids in better understanding for all stakeholders but also facilitates improved communication among the project team. Engineers, architects, and contractors can collaborate more effectively, leading to a smoother and more synchronized construction process.

2. Time and Cost Savings

The proactive nature of 3D rebar detailing contributes significantly to time and cost savings throughout the construction lifecycle. By identifying and addressing potential issues before breaking ground, delays and rework are minimized. The accuracy of the 3D models also streamlines the procurement process, reducing material waste and ensuring optimal resource utilization.

Implementation in Real-world Projects

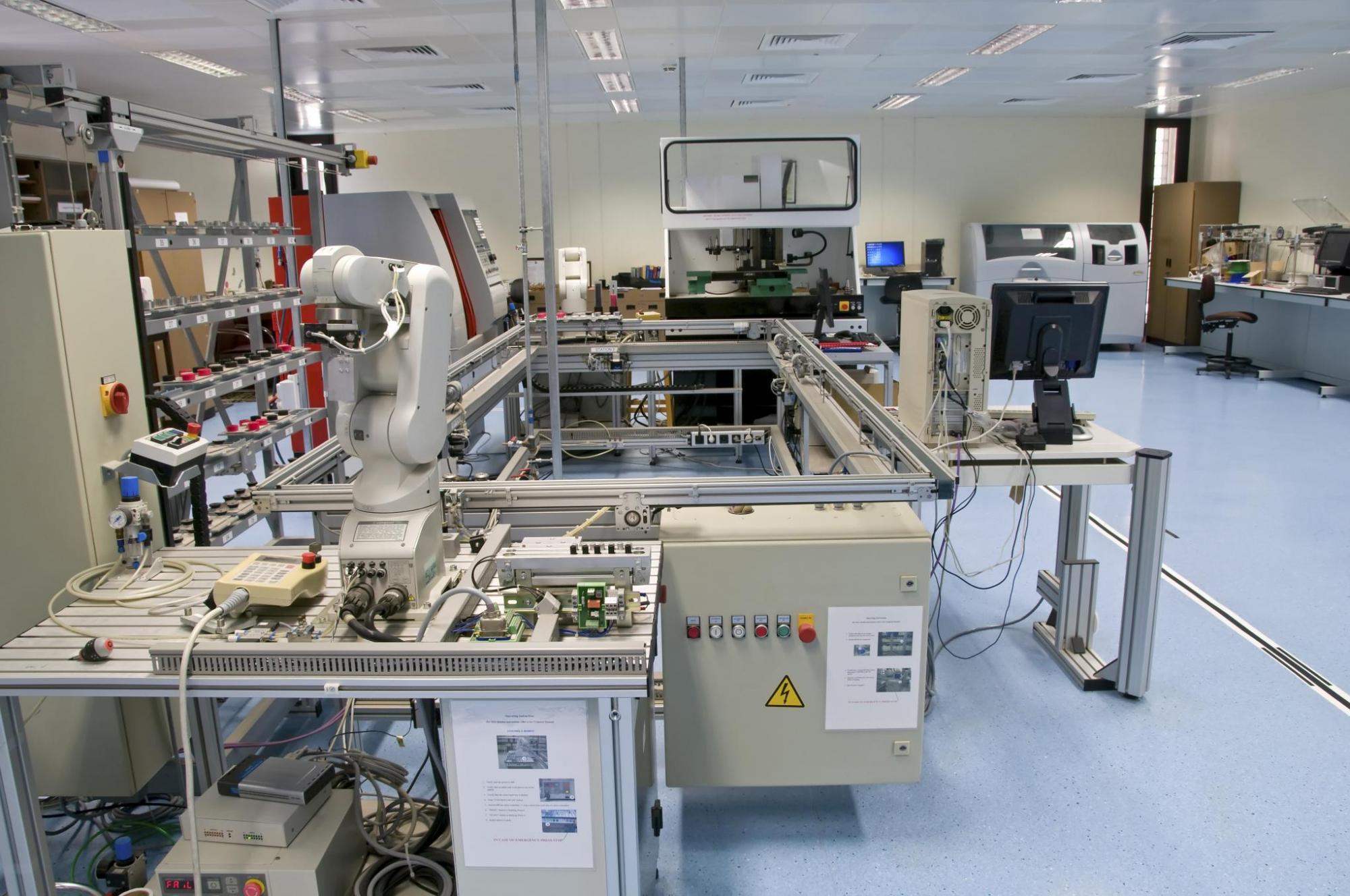

The real test of any innovation lies in its practical application. 3D rebar detailing has successfully proven its worth in diverse construction projects worldwide. Whether it’s high-rise buildings, bridges, or industrial structures, the technology’s adaptability is evident. Real-world examples showcase the seamless integration of 3D detailing, resulting in smoother construction processes and superior structural integrity.

A notable advantage of implementing 3D rebar detailing is the ability to detect clashes and conflicts in the design phase itself. This proactive approach eliminates costly rework during construction, as clashes are identified and resolved digitally before the physical implementation begins. This not only ensures a more efficient construction process but also contributes to a safer working environment.

The Future Landscape of 3D Rebar Detailing

As technology continues to advance, the future of 3D rebar detailing looks promising with several exciting developments on the horizon. Artificial intelligence (AI) integration is poised to enhance the efficiency of 3D rebar detailing by automating repetitive tasks and providing intelligent insights. Additionally, the integration of Internet of Things (IoT) devices into construction processes will further elevate the accuracy and real-time monitoring capabilities of 3D rebar detailing.

Future Trends and Advancements

As technology continually evolves, so does 3D rebar detailing. Future trends in this field are poised to further enhance efficiency and accuracy in construction projects. One such trend is the integration of artificial intelligence (AI) into detailing software. AI algorithms can analyze vast amounts of data, providing insights that go beyond human capabilities. This can lead to even more optimized reinforcement strategies, reducing material wastage and further streamlining construction processes.

Moreover, the integration of 3D printing technology with 3D rebar detailing holds the promise of revolutionizing on-site construction. The ability to print intricate rebar structures directly onto concrete elements can potentially redefine the speed and precision of construction, opening up new possibilities in architectural design and structural innovation.

Challenges and Future Trends

While the benefits of 3D rebar detailing are evident, challenges persist, including the initial learning curve associated with adopting new software and the need for skilled personnel. However, as the industry continues to embrace this technology, training programs and educational initiatives are emerging to bridge the skills gap.

Looking ahead, the future of 3D rebar detailing holds exciting possibilities. Machine learning and artificial intelligence are expected to further enhance the capabilities of BIM software, automating repetitive tasks and providing even more sophisticated analysis tools. The integration of augmented reality into the detailing process may also become a reality, allowing engineers to visualize and interact with the 3D model on the construction site.

Conclusion: Elevate Your Projects with Precision and Efficiency

In conclusion, mastering 3D rebar detailing is no longer an option but a necessity for modern structural engineering practices. Embracing advanced techniques, understanding the benefits, and staying abreast of future developments will empower engineers to elevate their projects with unparalleled precision and efficiency.

By incorporating 3D rebar detailing into your workflow, you not only enhance the quality of your structures but also position yourself at the forefront of the construction technology revolution. As we continue to embrace innovation, the synergy between 3D rebar detailing and structural engineering will undoubtedly shape the future of the construction industry. Stay informed, stay ahead, and revolutionize your approach to building the structures of tomorrow.