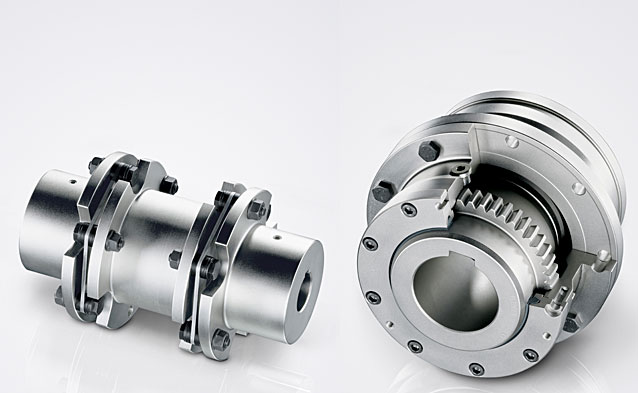

In the intricate machinery that powers various industries, the synergy between couplings and bearings is fundamental. As businesses seek reliable components, coupling suppliers near me and bearing manufacturers in China emerge as key players in the global supply chain. This article explores the significance of these components, delves into the innovations led by Chinese bearing manufacturers, and emphasizes the importance of local coupling suppliers in ensuring seamless mechanical operations.

Coupling Suppliers Near Me: The Backbone of Mechanical Systems

Proximity and Reduced Lead Times:

Coupling suppliers near me provide a distinct advantage through local accessibility. The proximity of suppliers ensures reduced lead times, allowing businesses to acquire critical components swiftly. In industries where downtime can incur significant costs, the ability to source couplings promptly from nearby suppliers becomes a strategic advantage.

Responsive Support and Customization:

Local coupling suppliers offer responsive support, enabling businesses to address specific needs promptly. Whether it’s technical assistance or customized solutions tailored to unique applications, the proximity of these suppliers fosters effective communication and collaboration. This localized support enhances the efficiency and reliability of mechanical systems.

Variety in Coupling Types:

Coupling suppliers near me typically offer a diverse range of coupling types to cater to various mechanical applications. From flexible and rigid couplings to jaw, gear, and disc couplings, businesses can choose components that align with the specific requirements of their machinery. This versatility ensures that local suppliers can accommodate the needs of different industries.

Bearing Manufacturers in China: Engineering Excellence on a Global Scale

Scale of Production and Market Presence:

China has emerged as a powerhouse in the global bearing industry, contributing significantly to both production scale and market presence. Bearing manufacturers in China leverage advanced technologies, innovative processes, and economies of scale to produce bearings that meet international standards. The sheer volume of production positions China as a key player in supplying bearings to diverse industries worldwide.

Quality Standards and Certification:

Chinese bearing manufacturers prioritize quality standards, investing in research and development to ensure their products adhere to stringent quality benchmarks. Many reputable Chinese bearing manufacturers hold international certifications, providing assurance to global customers regarding the reliability, durability, and performance of their bearings.

Innovations in Bearing Technology:

Advanced Materials and Manufacturing Techniques:

Bearing manufacturers in China are at the forefront of adopting advanced materials and manufacturing techniques. The use of high-quality steel alloys, ceramic materials, and advanced lubrication technologies enhances the performance and longevity of bearings. Continuous innovation in manufacturing processes, such as precision machining and heat treatment, contributes to the efficiency and reliability of modern bearings.

Integration of Smart Technologies:

The integration of smart technologies is transforming the landscape of bearing manufacturing. Chinese bearing manufacturers are exploring the incorporation of sensors and monitoring systems into bearings. Smart bearings equipped with condition monitoring capabilities enable real-time tracking of factors such as temperature, vibration, and load. This proactive approach to maintenance enhances the reliability and efficiency of machinery.

Local and Global Collaboration: A Symbiotic Relationship

Optimizing the Supply Chain:

The collaboration between coupling suppliers near me and Chinese bearing manufacturers forms a symbiotic relationship that optimizes the supply chain. Local businesses benefit from the efficiency and responsiveness of nearby coupling suppliers, while also tapping into the global expertise and scale of Chinese bearing manufacturers. This strategic sourcing approach ensures that businesses receive high-quality components that align with both local needs and global standards.

Tailored Solutions for Regional Industries:

Coupling suppliers near me, intimately familiar with the needs of their regional industries, collaborate with Chinese bearing manufacturers to provide tailored solutions. This collaboration allows for the seamless integration of couplings and bearings into machinery designed for specific applications, ensuring optimal performance and durability in diverse industrial settings.

Challenges and Solutions in Component Integration:

Compatibility and Precision Engineering:

Achieving optimal performance in mechanical systems requires the harmonious integration of couplings and bearings. Local suppliers and Chinese manufacturers collaborate to ensure compatibility between these components. Precision engineering and meticulous design considerations are employed to guarantee that couplings and bearings work seamlessly together, minimizing wear and maximizing efficiency.

Mitigating Wear and Alignment Issues:

The challenge of wear and misalignment, common in mechanical systems, is addressed through collaborative efforts. Local suppliers provide insights into the specific operational challenges faced by regional industries. Guiding Chinese bearing manufacturers in developing bearings that withstand the unique conditions. This collaborative approach results in components that mitigate wear, reduce friction, and enhance the overall lifespan of machinery.

Future Directions: Embracing Technological Advancements

Innovative Coupling Designs:

The future of coupling technology is poised for innovation, with an emphasis on designs that enhance flexibility, durability, and torsional rigidity. Advancements in materials, such as composite materials and advanced alloys, contribute to the development of couplings that can withstand higher loads, offer improved shock absorption, and operate with greater efficiency.

Smart Couplings for Predictive Maintenance:

Similar to smart bearings, the integration of sensors and monitoring systems into couplings is becoming a focal point of research and development. Smart couplings equipped with sensors provide real-time data on factors such as torque, speed, and misalignment. This data facilitates predictive maintenance, allowing businesses to address potential issues before they escalate, minimizing downtime and optimizing machinery performance.

Innovative Bearings for Evolving Needs:

Application-Specific Bearings:

Bearing manufacturers in China are expected to continue producing bearings tailored to the specific needs of evolving industries. Application-specific bearings designed for sectors such as renewable energy, robotics, and electric vehicles are anticipated to be at the forefront of innovation. These bearings will be engineered to withstand unique challenges posed by emerging technologies and industrial trends.

Energy-Efficient and Sustainable Bearings:

The future landscape of bearing manufacturing is likely to prioritize energy efficiency and sustainability. Bearing manufacturers in China, cognizant of global sustainability goals, are expected to explore materials and production processes that reduce environmental impact. Energy-efficient bearings designed to minimize friction and improve overall machinery efficiency will be instrumental in creating a more sustainable industrial ecosystem.

Conclusion:

In conclusion, the confluence of expertise between coupling suppliers near me and bearing manufacturers in China is driving mechanical excellence on both local and global scales. The collaboration ensures that businesses benefit from the efficiency, responsiveness, and tailored solutions offered by local coupling suppliers. While also tapping into the advanced technologies, scale, and quality standards upheld by Chinese bearing manufacturers.

Click here to read more